Dissolved Oxygen Levels In Rivers and Lakes

November 1, 2019

pH and ORP Monitoring in Water Quality Management

April 4, 2024Industrial Signal Isolation

In industry, signal isolation is critical for maintaining seamless communication and data integrity. With many different pieces of equipment in use in industrial environments separated by distances and operating off different supplies, isolating signals is vital in safeguarding sensitive equipment, enhancing reliability, mitigating risks and ensuring safety of personnel. Here, we review signal isolation in industrial settings, exploring its many benefits.

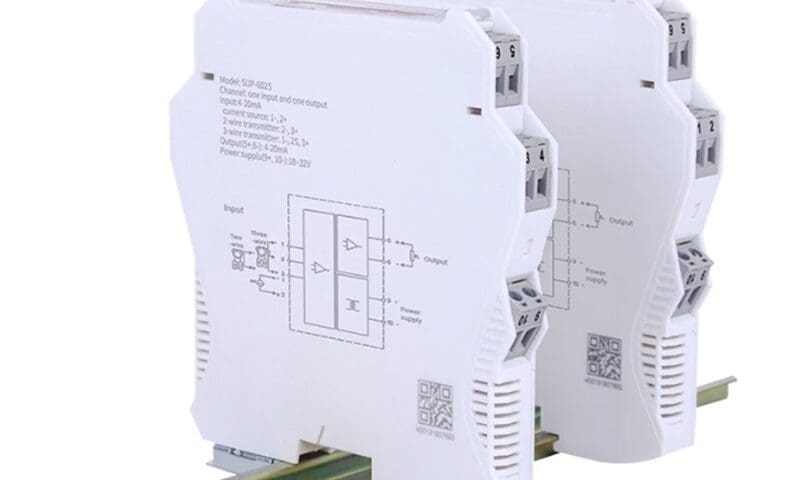

Industrial Solutions for Isolating Signals

Industrial signal isolation solutions serve as the backbone of reliable communication and data transmission in industrial environments. These solutions encompass a range of techniques and devices designed to electrically separate input and output circuits, thereby preventing disruptive ground loop currents from compromising signal integrity. From isolators and converters to transformers and fiber optic isolators, industrial signal isolation solutions offer robust protection against noise, interference, and ground loops, ensuring the accuracy and reliability of critical data streams.

Isolation Techniques for Signals in Factories

In factories, where precision, efficiency and safety are paramount, signal isolation techniques play a pivotal role. . By employing isolation barriers, optocouplers, and galvanic isolators, factories can effectively isolate signals, mitigating the risks posed by electromagnetic interference and ground loops. This not only enhances the accuracy and reliability of data acquisition but also reduces the likelihood of equipment damage and downtime, thus bolstering overall productivity and competitiveness. Personnel can also connect and disconnect devices in the field without exposing personnel to dangerous voltage while working on other equipment.

Signal Isolation Devices for Industrial Use

Without signal isolators ground loops would be an enormous problem. These devices break the paths of the ground loops while still allowing the data to be electronically transferred from one transmitting output to another piece of equipment’s receiving input. Some isolators trnsfer voltages or currents with a slow response which is ideal for eliminating noise relaative to ground.. Others have to work at high speeds feeding information to high-speed a to d converters capable of handling large data volumes. Whatever the speed of operation required, signal isolation devices for industrial use provide a versatile and reliable solution for ensuring seamless communication and data transmission.

Maintaining Isolation for Industrial Automation

In the era of Industry 4.0, where automation and connectivity are transforming industrial processes, the role of devices that isolate signals becomes increasingly critical. In industrial automation applications, where precision and reliability are essential for seamless operation, signal isolation removes common mode noise and thus ensures the integrity of critical data streams and communication channels. By isolating signals in automated systems, industrial organisations can mitigate the risks of data corruption, system errors, and operational disruptions, thus unlocking the full potential of automation technologies to drive innovation and efficiency.

Here is a link to the Signal Isolators supplied by Meascom